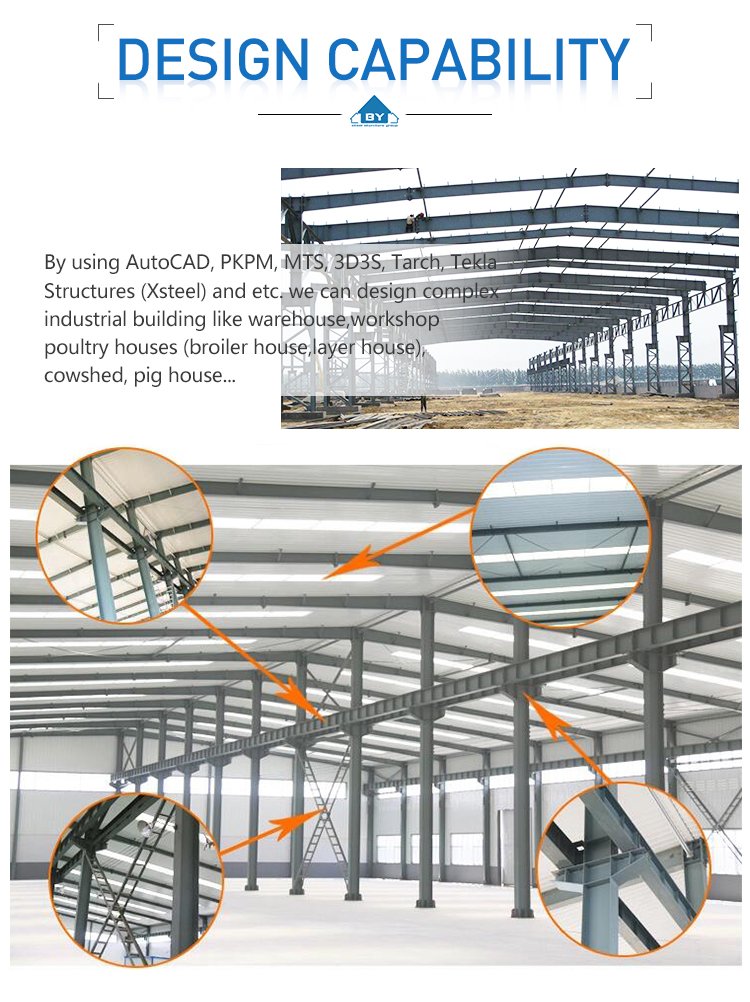

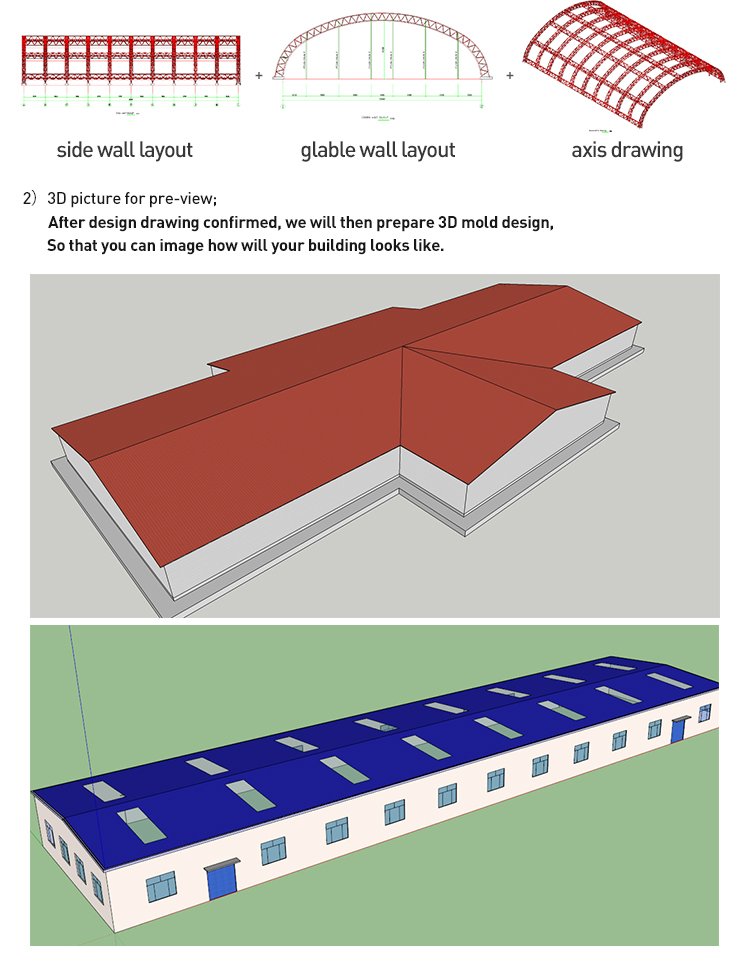

Design Future:

The Germany workshop, standing proudly at a height of 15 meters, is a testament to the company's commitment to precision engineering and state-of-the-art manufacturing facilities. With a total weight capacity of 3500 tons, this structure is designed to withstand the heaviest of industrial equipment and operations.

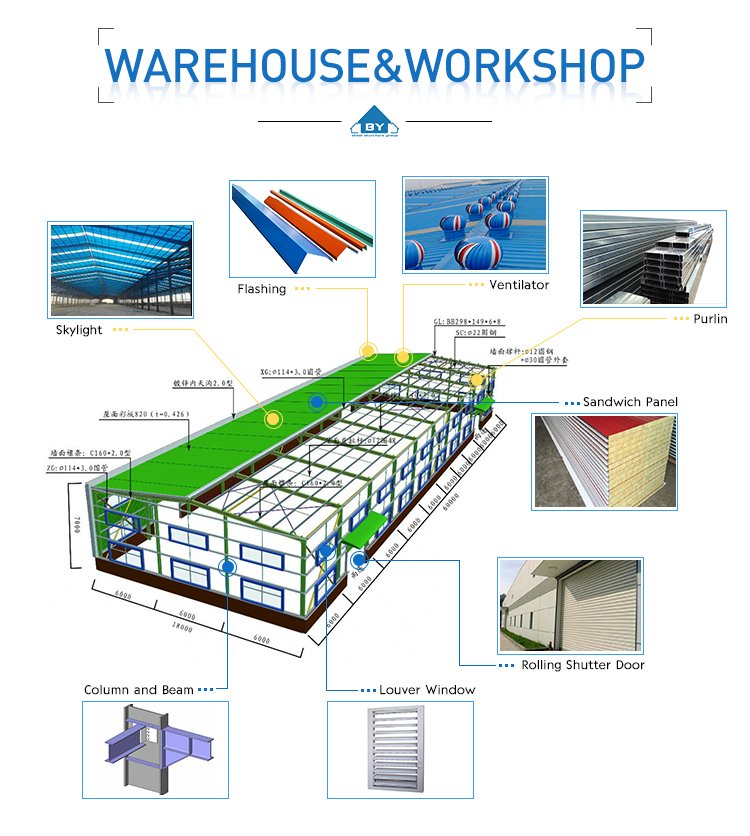

Predominantly constructed with steel structures, the workshop offers both strength and durability, ensuring its longevity even under the harshest of conditions. The roof and wall facade are clad with sandwich panels, providing excellent insulation and weather resistance, while maintaining a sleek and modern aesthetic.

Spanning over an impressive total area of 45835 square meters, the workshop offers ample space for all types of manufacturing activities. The interior layout is designed to maximize efficiency and workflow, with clearly defined zones for various production processes.

Looking ahead, the design future of this workshop promises to be equally exciting. Siemens remains committed to innovation and sustainability, and as such, future upgrades and expansions will likely incorporate the latest advancements in green building technology. This could include the use of renewable energy sources, energy-efficient lighting and heating systems, and even the integration of smart building management systems.

In conclusion, the workshop in Germany is not just a manufacturing facility, but a symbol of the company's commitment to excellence and its vision for the future of industrial design and construction.

Steel structure Specification:

1. Material: Q235B or Q355B

2. Project size: length: normally from 20 to 300m, width from 10m to 60m; height from 2.5m to 30m eave height.

3. Span:single span or multi span

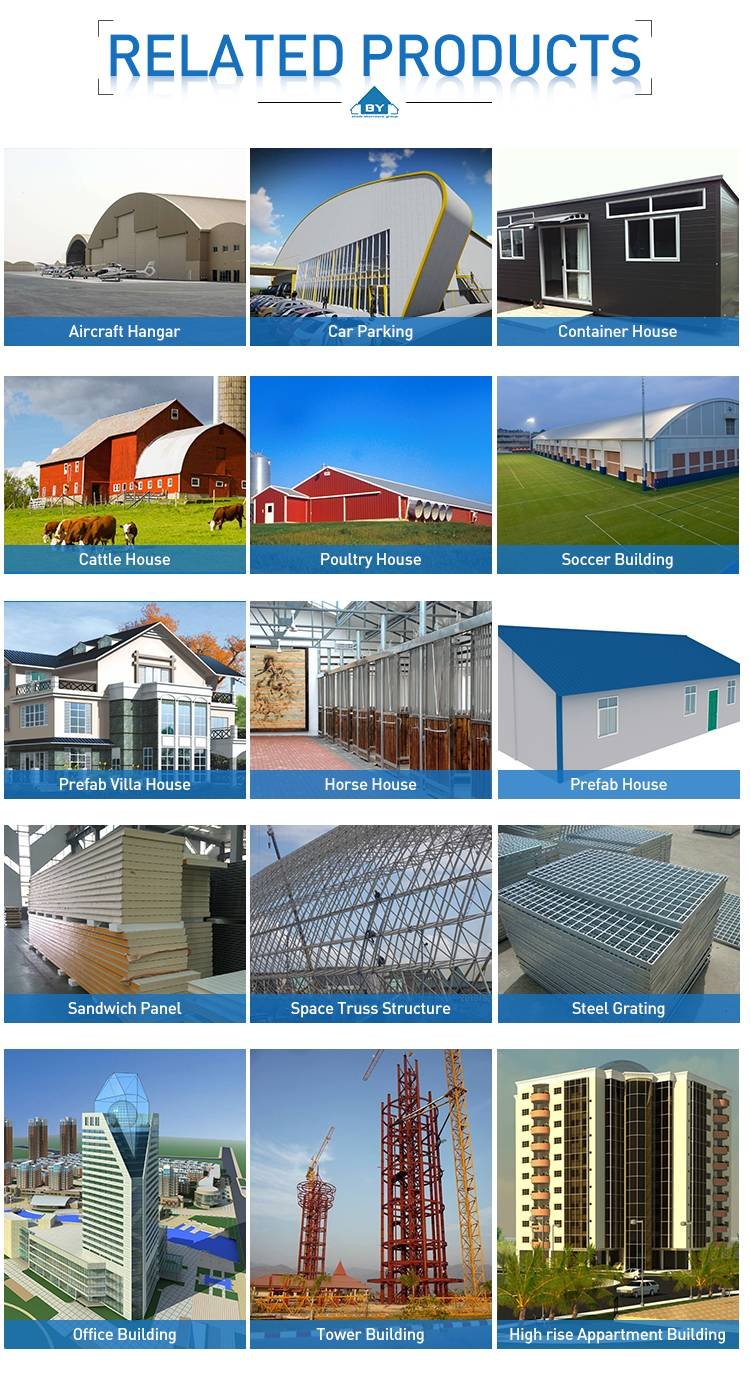

4. Building Type: warehouse, workshop, Agricultural projects (horse/cattle barn, poultry house), high rise building, heavy industrial steel structure buildings, car parking, Large scale span projects...

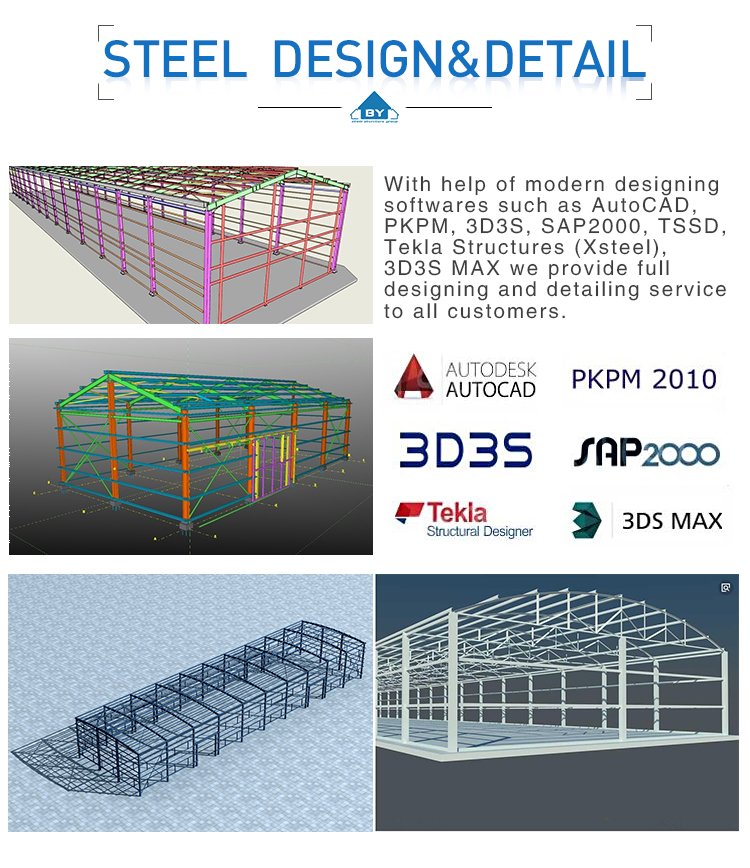

5. Design: Fabricate based on clients design or we make design based on Customer’s Technical data.

The structure materials:

1. Main structure: built up or hot rolled H beam.

2. Purlin: galvanized C purlin and Z purlin

3. Wall and Roof Materials: EPS / Rock wool /Fiber glass/PU sandwich panel or corrugated steel sheet/ Aluminium plate/ Curtain wall

4. Tie rod: circular steel tube

5. Wall &roof sag rod: round bar or angel steel finish with hot dipped galvanizing or anti rust primer paint

7. Column & roof bracing : Steel Bar/ angle steel / square tube.

8. Fly bracing: angle steel L50x5

10.. Roof gutter: steel sheet, Galvanized steel sheet, Aluminum sheet and stainless steel sheet.

11. Rain spout: PVC pipe / Aluminium pipe/steel pipe

12. Doors: sliding sandwich panel doors, rolling shutter door, high speed shutter door or metal doors, Aircraft Gate.

13. Windows: PVC window, aluminum window

14. Surface finishing: hot dipped galvanizing or anti rust primer coating.

15.Design: Tailored to client's needs or professionally designed by our team

16.Quality Assurance: Ensured by manufacturers with stringent quality control measures or through the utilization of third-party inspection services

17.Installation: Assisted by our engineers during the installation process or on-site supervision provided by our dedicated engineering team

18.Warranty: Guaranteeing a structural lifespan exceeding 50 years for the primary structure

The information required for the quotation is as follows.

1. Building area: Length x width x eave height (mm ) or Please send us your detailed drawings?

2. Wind speed (Km/h)and snow load (kg/m2) at construction site?

3. Roof and wall material: What type of wall and roof materials do you need?

4. Windows and doors: How many doors and windows do you need? What is size and materials?

5. Do you need the ventilator for the warehouse?

6. Steel structure finishing: do you want primer coating (paint, what kind of paint or just normal brand?) or hot dip galvanized?