Steel structure Specification:

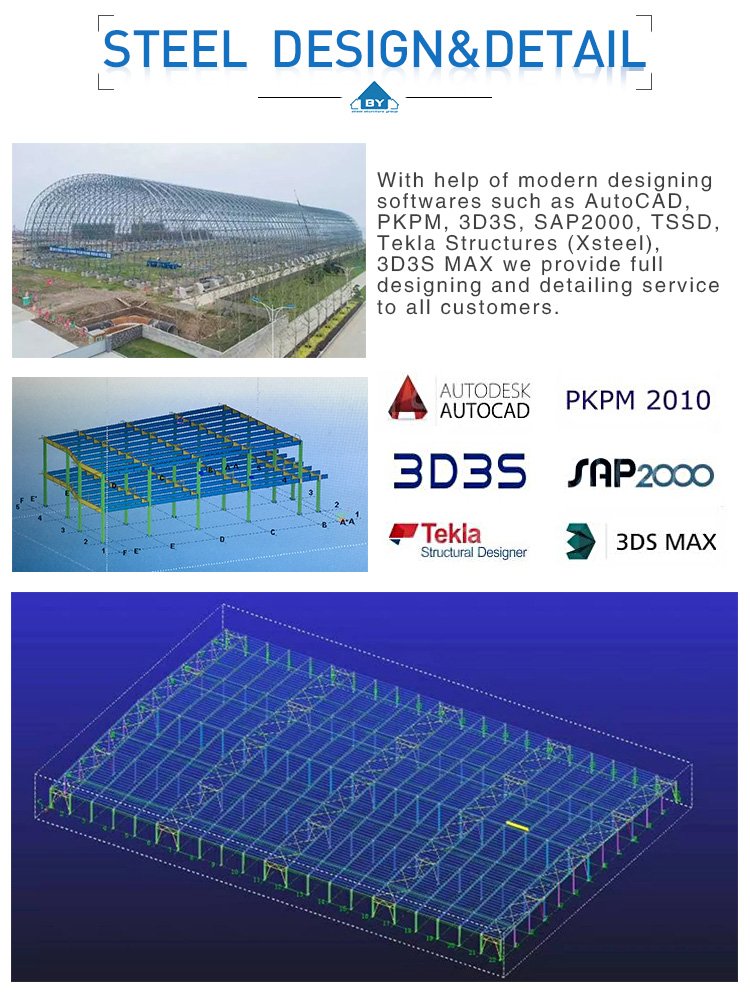

1. Material: Q235B or Q355B

2. Project size: length: 50m,60m,75m,100m,120m,150m, width 12m, 12.5m,14m,15m,16m

3. Span:single span

4. Building Type: Agricultural projects (horse/cattle barn, poultry house),

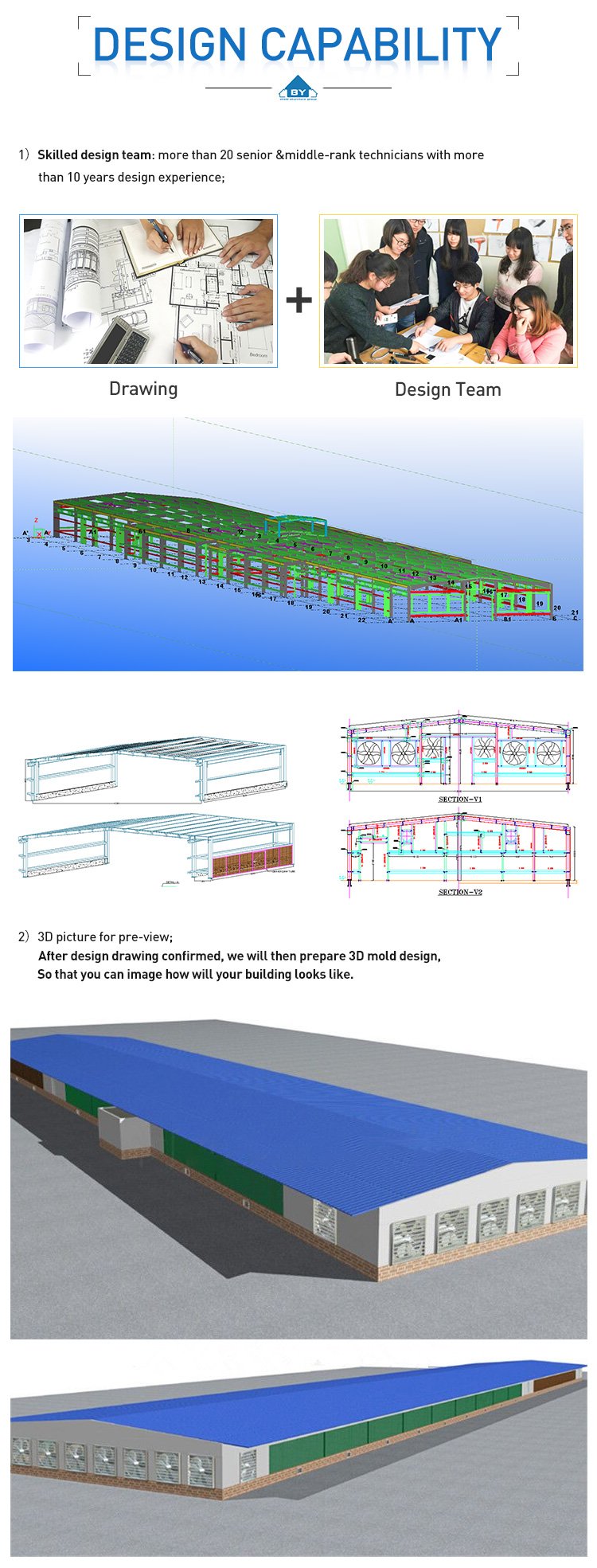

5. Design: Fabricate based on clients design or we make design based on Customer’s Technical data.

The structure materials:

1. Main structure: built up or hot rolled H beam.

2. Purlin: galvanized C purlin and Z purlin

3. Wall and Roof Materials: EPS / Rock wool /Fiber glass/PU sandwich panel or corrugated steel sheet/ Aluminium plate/ Curtain wall

4. Tie rod: circular steel tube

5. Wall &roof sag rod: round bar or angel steel finish with hot dipped galvanizing or anti rust primer paint

7. Column & roof bracing : Steel Bar/ angle steel / square tube.

8. Fly bracing: angle steel L50x5

10.. Roof gutter: steel sheet, Galvanized steel sheet, Aluminum sheet and stainless steel sheet.

11. Rain spout: PVC pipe / Aluminium pipe/steel pipe

12. Doors: sliding sandwich panel doors, rolling shutter door, high speed shutter door or metal doors, Aircraft Gate.

13. Windows: PVC window, aluminum window

14. Surface finishing: hot dipped galvanizing or anti rust primer coating.

15.Design: Tailored to client's needs or professionally designed by our team

16.Quality Assurance: Ensured by manufacturers with stringent quality control measures or through the utilization of third-party inspection services

17.Installation: Assisted by our engineers during the installation process or on-site supervision provided by our dedicated engineering team

18.Warranty: Guaranteeing a structural lifespan exceeding 50 years for the primary structure

The information required for the quotation is as follows.

1. Building area: Length x width x eave height (mm ) or Please send us your detailed drawings?

2. Wind speed (Km/h)and snow load (kg/m2) at construction site?

3. Roof and wall material: What type of wall and roof materials do you need?

4. Windows and doors: How many doors and windows do you need? What is size and materials?

5. Steel structure finishing: do you want primer coating (paint, what kind of paint or just normal brand?) or hot dip galvanized?

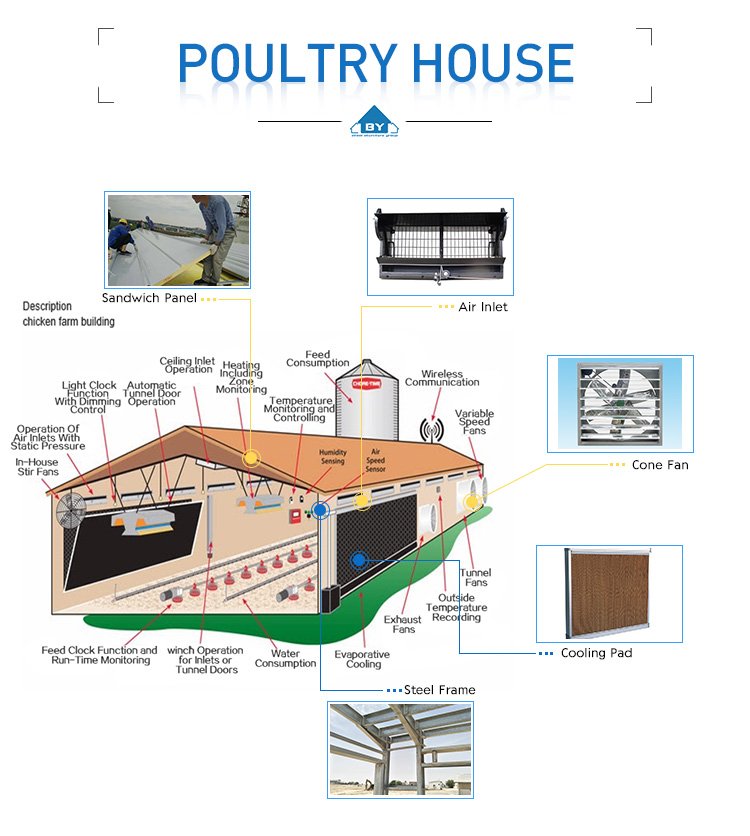

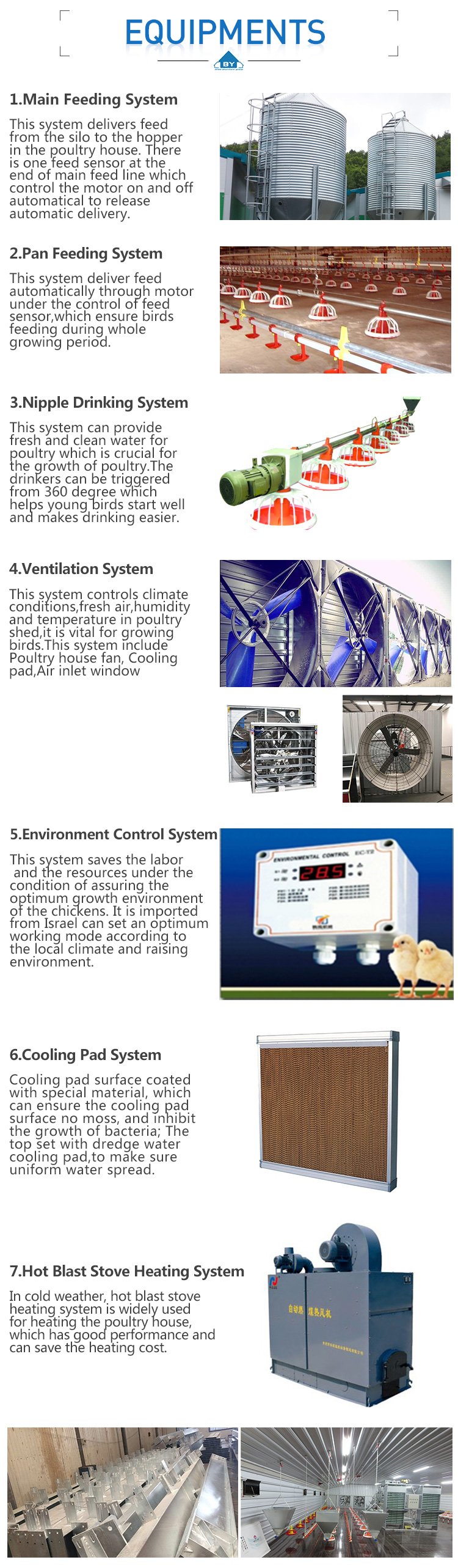

Design Features of Steel Structure Chicken House

When discussing the design features of steel structure chicken houses, we have to mention the structural stability and durability. With unique advantages, steel structure chicken houses have become the leaders in modern aquaculture industry.

Structural Stability

The steel structure chicken house adopts high-strength steel as the main load-bearing member, which is precisely designed and calculated to ensure its structural stability and bearing capacity. This structure can resist the influence of strong winds, heavy snows and other severe weather conditions, providing a safe and stable growth environment for the chickens.

Durability

Steel has good corrosion resistance and aging resistance, which can maintain its original performance and appearance during long-term use. Therefore, the service life of steel structure chicken houses is relatively long, meeting the long-term development needs of the aquaculture industry.

Environmental Friendliness

In the selection of materials, steel structure chicken houses also take environmental factors into full consideration. Steel is a recyclable and reusable material, with relatively few wastes generated during its production and use, which has a small impact on the environment. At the same time, the design of steel structure chicken houses also focuses on energy saving and emission reduction. Through reasonable ventilation, lighting and thermal insulation design, energy consumption and emissions are reduced.

Easy Installation

The installation process of steel structure chicken houses is relatively simple and fast. We can send professional installation teams for on-site construction or provide technical guidance so that customers can install them by themselves. Regardless of the method, we will ensure safe, efficient and accurate installation process.

Besides the above design features, steel structure chicken houses also have the advantages of flexibility and scalability. Its modular design allows the chicken house to be combined and disassembled according to needs, adapting to different scales and purposes. At the same time, with the continuous development of aquaculture industry, chicken houses can also be expanded and renovated to meet the needs of space and function in aquaculture industry.

In conclusion, with its unique design features and advantages, steel structure chicken houses have become an indispensable part of modern aquaculture industry. We believe that in the future development, steel structure chicken houses will continue to play an important role in making greater contributions to the development of aquaculture industry.